There is a raft of terminology that is used when discussing the industrial fans and air movement solutions AirEng provides. Although used daily by our team, this jargon may be new to those who require our services. This article identifies and explains a variety of terms related to air-movement solutions.

Industrial Fan Terminology Explained – Part 1, A-G

Air Velocity

The rate of motion of air in a given direction

Amperage

The strength of an electric current in amperes

Axial Fan

A type of industrial fan that moves air in a linear direction, meaning the air flow does not change direction but is forced to move parallel to the shaft.

Blower

Directs air flow in one specific direction with the use of impellers

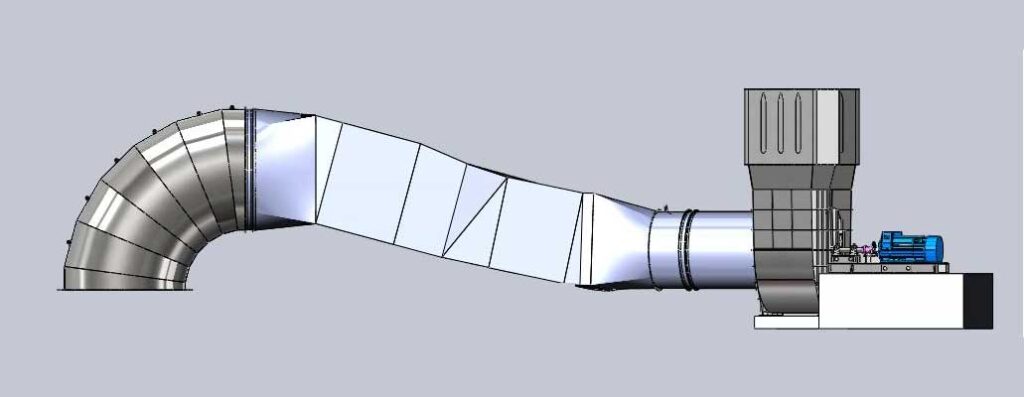

Centrifugal Fan

A type of industrial fan that has an impeller which increases the speed of the air that has entered the fan. Initially entering the fan in an axial direction, the air then changes direction using Centrifugal force and is released in a radial direction.

Circulation

The process of moving air around a specific area

Cross Ventilation

The process of air entering a room via an inlet and an outlet forcing air back out of the room (for example via an open window or roof vent)

Damper

A valve or plate that regulates the flow of air in a fan system

Fan Blade

The component of an industrial fan that is attached to the hub and rotates to cut the air and create movement. Blades may be in a flat radial position, or curve forward or backward depending on air movement requirements

Fan Vibration Analysis

Using a diagnostic tool called an accelerometer, the vibrations in the horizontal, axial and vertical directions are measured when the fan is being operated at its design speed